Manufacturing inventory software plays a crucial role in streamlining production operations by efficiently managing raw materials, work-in-progress, and finished goods. This software provides real-time visibility into data, enhancing decision-making processes for manufacturers.

Overview of Manufacturing Inventory Software

Manufacturing inventory software plays a crucial role in optimizing production processes by efficiently managing and tracking inventory levels throughout the manufacturing cycle. This software automates inventory management tasks, streamlines operations, and provides real-time insights to help businesses make informed decisions.

Tracking Inventory Levels

Manufacturing inventory software helps in tracking raw materials, work-in-progress, and finished goods at every stage of the production process. It enables businesses to monitor stock levels, identify shortages or excess inventory, and maintain optimal levels to meet production demands efficiently.

Real-Time Data Visibility

One of the key benefits of manufacturing inventory software is the real-time data visibility it offers. Businesses can access up-to-date information on inventory levels, production schedules, and order statuses instantly. This visibility allows for better planning, forecasting, and decision-making to improve overall operational efficiency.

Features of Manufacturing Inventory Software

Manufacturing inventory software comes with a variety of features designed to streamline operations and improve efficiency in the manufacturing process. Some of the essential features include:

1. Barcode Scanning, Manufacturing inventory software

Barcode scanning functionality allows for quick and accurate tracking of inventory items within the manufacturing facility. By scanning barcodes, employees can easily update inventory levels, track items in real-time, and reduce errors associated with manual data entry.

2. Serial Number Tracking

Manufacturing inventory software enables businesses to track individual items by their unique serial numbers. This feature is especially useful for industries that require traceability, such as electronics or automotive manufacturing. It helps in identifying defective products, managing warranties, and ensuring compliance with regulations.

3. Batch Tracking

Batch tracking functionality allows manufacturers to monitor groups of products that share common characteristics, such as production date or supplier. This feature is crucial for industries where batch quality control is critical, such as pharmaceuticals or food processing. It helps in identifying and isolating faulty batches, ensuring product safety and quality.

Forecasting Tools for Demand Planning

Manufacturing inventory software often includes forecasting tools that utilize historical data and trends to predict future demand for products. These tools help businesses in optimizing inventory levels, reducing stockouts, and improving customer satisfaction. By accurately forecasting demand, manufacturers can plan production schedules, manage inventory efficiently, and minimize excess stock.

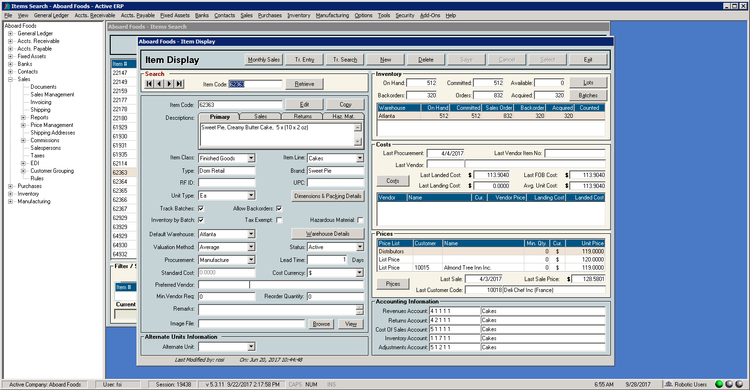

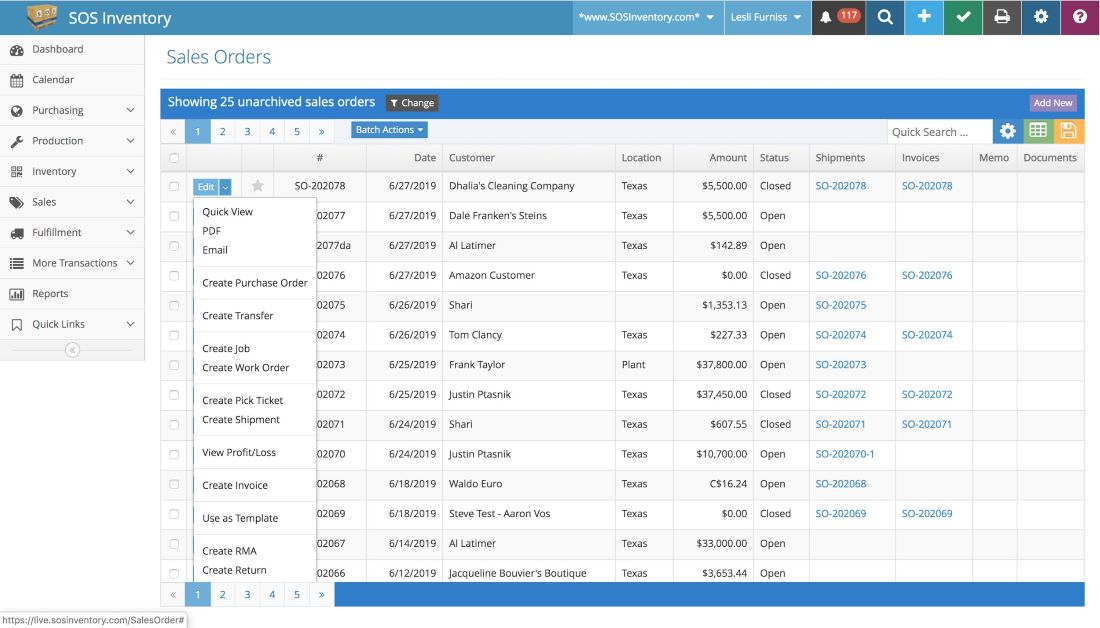

Integration Capabilities with ERP and CRM Systems

Manufacturing inventory software can seamlessly integrate with other systems like Enterprise Resource Planning (ERP) and Customer Relationship Management (CRM) software. This integration enables data sharing across different departments, streamlines processes, and improves overall efficiency. By connecting inventory management with other business functions, manufacturers can achieve better visibility, coordination, and decision-making across the organization.

Implementation of Manufacturing Inventory Software

Implementing manufacturing inventory software in a production environment is a crucial step towards streamlining operations and improving efficiency. It involves several key steps to ensure a successful integration.

Steps Involved in Implementing Manufacturing Inventory Software

- Assessment of Current Processes: The first step is to assess the current inventory management processes to identify areas that need improvement.

- Selection of Suitable Software: Choose a software solution that aligns with the specific needs and requirements of your manufacturing operations.

- Customization and Configuration: Customize the software according to your inventory tracking needs and configure it to integrate seamlessly with existing systems.

- Training and Onboarding: Provide comprehensive training to employees on how to effectively use the software to maximize its benefits.

- Testing and Quality Assurance: Conduct thorough testing to ensure the software functions correctly and meets the desired performance standards.

- Go-Live and Support: Finally, launch the software in the production environment and provide ongoing support to address any issues that may arise.

Training Requirements for Employees

Effective use of manufacturing inventory software requires adequate training for employees to ensure they can utilize all features and functionalities efficiently. Training should cover aspects such as data entry, reporting, inventory tracking, and troubleshooting.

Best Practices for Data Migration

- Backup Existing Data: Before migrating to a new software system, ensure that all existing data is backed up to prevent any loss during the transition.

- Cleanse and Organize Data: Cleanse and organize the data to eliminate duplicates, errors, and inconsistencies for a smooth migration process.

- Map Data Fields: Identify and map data fields from the old system to the new system to ensure seamless transfer of information.

- Test Data Migration: Conduct thorough testing of data migration to validate the accuracy and completeness of transferred data.

- Train Employees: Provide training to employees on how to access and utilize data in the new system to ensure a smooth transition and minimize disruptions.

Benefits of Using Manufacturing Inventory Software

Manufacturing inventory software offers a wide range of benefits that can significantly improve the efficiency and effectiveness of your operations. From cost-saving advantages to enhanced accuracy in inventory tracking, this software can revolutionize how you manage your manufacturing processes.

Cost-Saving Benefits

Manufacturing inventory software plays a crucial role in optimizing inventory management, leading to cost savings through reduced wastage and improved resource utilization. By automating inventory tracking and streamlining processes, companies can minimize excess inventory levels, avoid stockouts, and ultimately reduce operational costs.

Enhanced Accuracy in Inventory Tracking

One of the key advantages of using manufacturing inventory software is the enhanced accuracy it provides in tracking inventory levels and order fulfillment. With real-time updates and visibility into inventory movements, companies can avoid errors, discrepancies, and stockouts, leading to improved customer satisfaction and operational efficiency.

Role of Analytics and Reporting Features

Manufacturing inventory software is equipped with advanced analytics and reporting features that provide valuable insights into your inventory management processes. By analyzing data such as demand patterns, lead times, and inventory turnover rates, companies can make informed decisions, optimize inventory levels, and improve overall supply chain efficiency.

Final Summary: Manufacturing Inventory Software

In conclusion, manufacturing inventory software offers a comprehensive solution for improving production efficiency, reducing wastage, and enhancing inventory accuracy. With its advanced features and integration capabilities, manufacturers can streamline their operations and make informed decisions to drive business growth.