Integrated engineering software revolutionizes the way industries operate by offering a seamless solution to complex engineering challenges. From streamlining workflows to maximizing efficiency, this innovative technology plays a crucial role in modern engineering practices.

As businesses strive for greater productivity and precision, integrated engineering software emerges as a game-changer, empowering professionals to achieve unprecedented levels of success.

Overview of Integrated Engineering Software

Integrated engineering software refers to a comprehensive solution that combines different engineering tools and applications into a single platform. This integration allows engineers to streamline their workflows, improve collaboration, and enhance productivity across various industries.

Using integrated engineering software offers several benefits, such as increased efficiency, cost savings, and better decision-making capabilities. By having all tools in one place, engineers can easily access and share data, design models, simulations, and analysis results. This leads to faster project completion, reduced errors, and improved overall quality of work.

Examples of popular integrated engineering software tools include Autodesk Product Design & Manufacturing Collection, Siemens Digital Industries Software, Bentley Systems, and Dassault Systèmes’ 3DEXPERIENCE platform. These tools offer a wide range of capabilities, from CAD and CAM to simulation, PLM, and IoT integration, catering to the diverse needs of engineers in different industries.

Features and Capabilities: Integrated Engineering Software

Integrated engineering software offers a wide range of features and capabilities that set it apart from traditional engineering software. These tools are designed to streamline workflows and enhance efficiency in engineering projects.

Key Features of Integrated Engineering Software

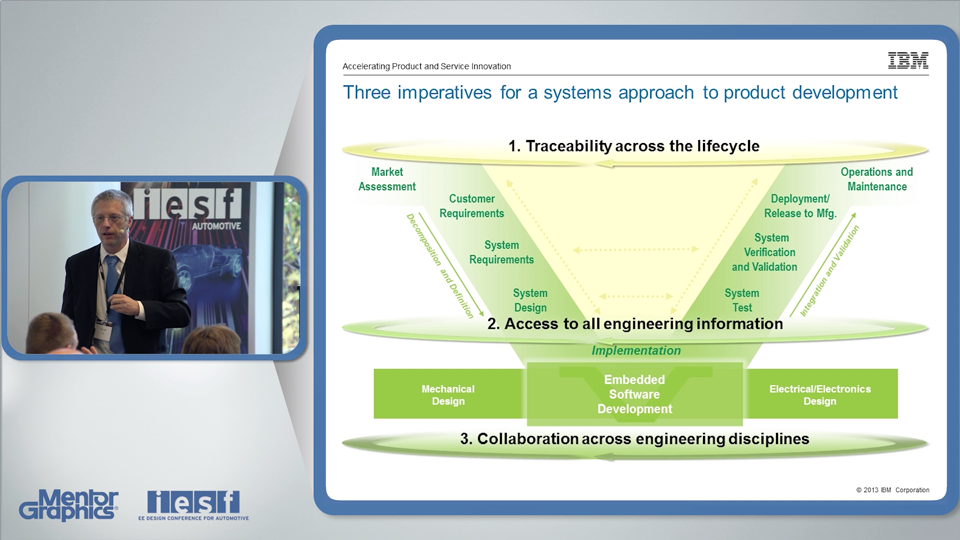

- Multi-disciplinary Integration: Integrated engineering software combines various engineering disciplines such as mechanical, electrical, and civil engineering into a single platform, allowing for seamless collaboration.

- Unified Data Management: These tools provide a central repository for all project data, ensuring consistency and accuracy throughout the design process.

- Simulation and Analysis: Integrated engineering software often includes advanced simulation and analysis capabilities, allowing engineers to test designs and troubleshoot problems before production.

- Automation and Optimization: Automation features help streamline repetitive tasks, while optimization tools help engineers find the most efficient design solutions.

- Real-time Collaboration: Integrated engineering software enables real-time collaboration among team members, regardless of their physical location, fostering better communication and teamwork.

Comparison with Traditional Engineering Software

- Traditional engineering software typically focuses on a single discipline, leading to siloed workflows and limited collaboration between teams.

- Integrated engineering software offers a holistic approach to design and development, breaking down barriers between different engineering disciplines.

- While traditional software may require manual data transfer between different tools, integrated software streamlines the process by centralizing data and automating tasks.

- Integrated software also tends to be more user-friendly and intuitive, reducing the learning curve for new users compared to traditional software.

Streamlining Workflows and Enhancing Efficiency

Integrated engineering software plays a crucial role in streamlining workflows and enhancing efficiency in engineering projects. By providing a unified platform for collaboration, data management, and analysis, these tools help teams work more cohesively and make informed decisions throughout the design process. The automation and optimization features further contribute to increased productivity and faster project delivery, making integrated engineering software a valuable asset for modern engineering teams.

Applications in Different Engineering Fields

Integrated engineering software plays a crucial role in various engineering disciplines, offering advanced tools and features to streamline design, analysis, and simulation processes across different fields. Let’s explore how this software is utilized in mechanical engineering, civil engineering projects, and electrical engineering.

Mechanical Engineering

Integrated engineering software in mechanical engineering is used for designing, analyzing, and optimizing mechanical systems and components. It enables engineers to create 3D models, perform finite element analysis (FEA), simulate fluid dynamics, and evaluate mechanical performance. For example, software like SolidWorks and ANSYS are commonly used in the industry to design and test mechanical structures, machinery, and equipment.

Civil Engineering Projects

In civil engineering projects, integrated engineering software is essential for planning, designing, and managing infrastructure projects such as buildings, bridges, roads, and dams. These software tools help engineers visualize project layouts, analyze structural integrity, assess environmental impacts, and optimize construction processes. Programs like AutoCAD Civil 3D and Revit are widely used for creating detailed construction plans, managing project data, and collaborating with stakeholders.

Electrical Engineering

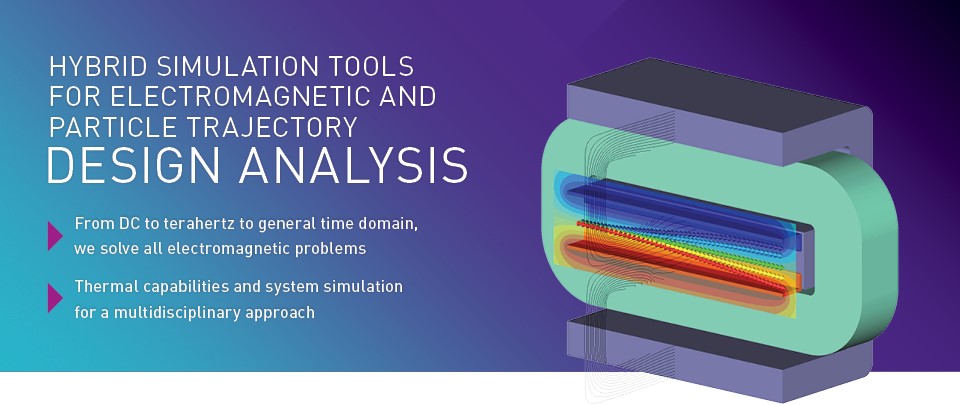

Integrated engineering software is utilized in electrical engineering for designing and simulating electrical systems, circuits, and components. Engineers use software tools to model power distribution networks, analyze electromagnetic interference, optimize circuit layouts, and simulate electronic devices. Examples include MATLAB/Simulink for control system design, PSpice for circuit analysis, and ETAP for power system analysis.

Integration with Other Systems

In today’s interconnected world, integrating engineering software with other systems is crucial for streamlining processes, improving efficiency, and enhancing collaboration across different departments. This integration allows for seamless data transfer, real-time updates, and a more holistic view of the entire engineering workflow.

Interface with CAD/CAM Software, Integrated engineering software

Integrated engineering software often interfaces with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software to enable a smooth transition from design to production. This integration ensures that design changes are automatically reflected in the manufacturing process, reducing errors and accelerating time-to-market. Engineers can easily transfer 3D models, drawings, and other design data between the two systems, facilitating a more efficient product development cycle.

Challenges and Benefits of Integrating with ERP Systems

Integrating engineering software with Enterprise Resource Planning (ERP) systems can be challenging due to differences in data formats, structures, and processes. However, the benefits far outweigh the challenges. By connecting engineering software with ERP systems, organizations can achieve better resource allocation, improved project management, and enhanced decision-making capabilities. This integration enables seamless communication between engineering, production, procurement, and other departments, leading to increased productivity and cost savings.

Ending Remarks

In conclusion, integrated engineering software stands as a cornerstone in the realm of engineering, driving advancements, and fostering innovation across diverse sectors. Embracing this cutting-edge technology is not just a choice but a necessity for staying ahead in today’s competitive landscape.